What are the stages of pressure ulcers, and how can they be treated quickly?

Pressure ulcers mainly occur due to skin pressure, but their formation is a complex process caused by the combined effects of local and systemic factors leading to skin tissue deformation and necrosis.

According to the international NPUAP/EPUAP pressure ulcer classification system, pressure ulcers are divided into six types: Stage I, Stage II, Stage III, Stage IV, Unstageable, and Suspect Deep Tissue Injury.

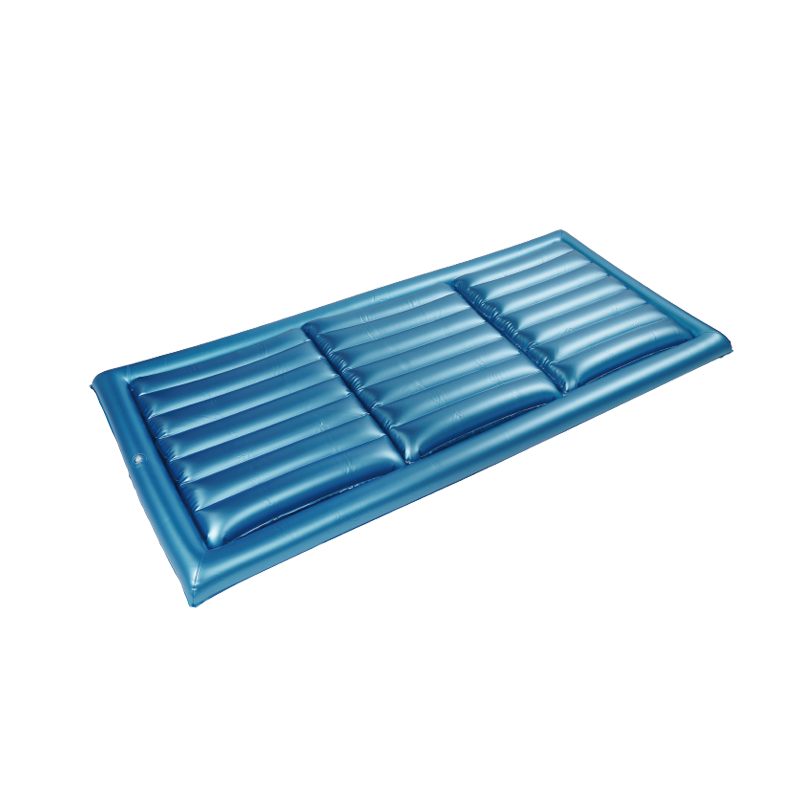

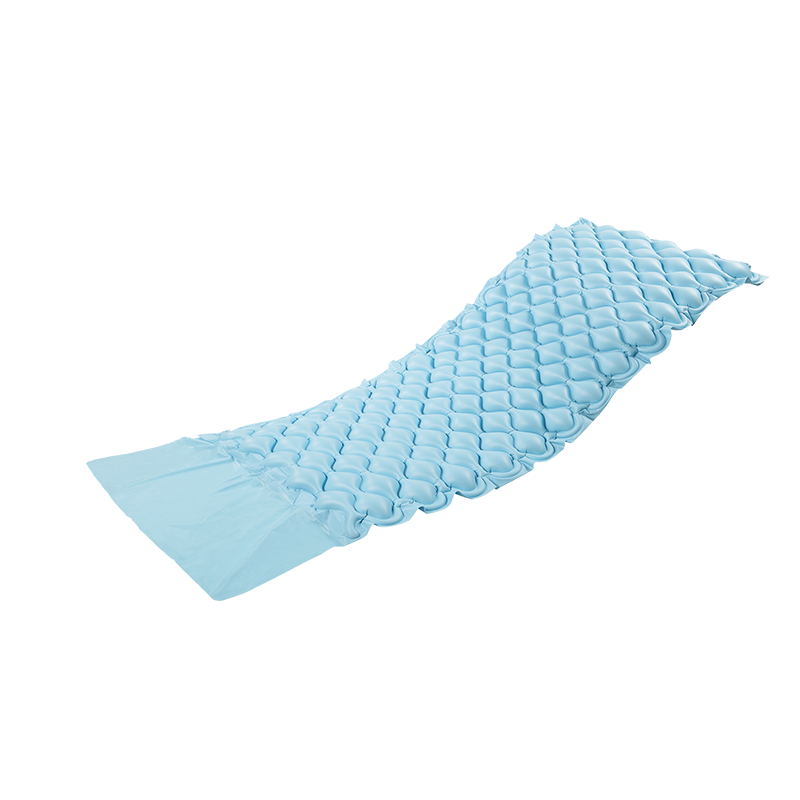

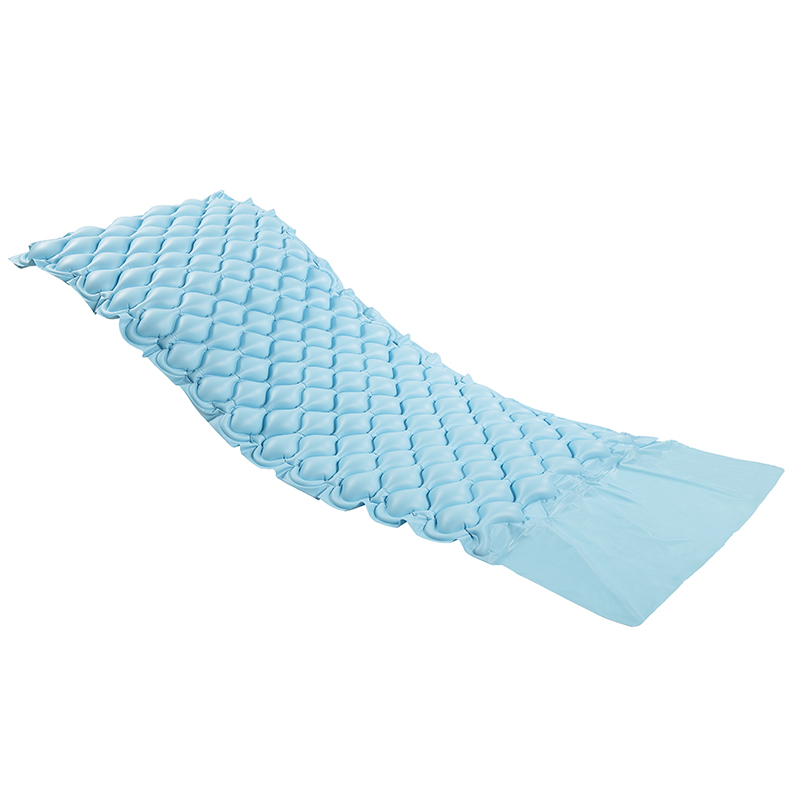

The FOFO medical air mattress is a key preventive measure for patients who are confined to bed for long periods to avoid pressure ulcers. It utilizes physiological and dynamic principles by employing an alternating air pump to manage the pressure through alternating inflation and deflation of two or more different pressure zones on the mattress. This effectively reduces the risk of pressure ulcers caused by prolonged excessive local pressure. The product has been strictly reviewed by the food and drug regulatory authorities in China and Europe and the United States, meeting the standards for production and clinical use. It is an essential household item for patients who have suffered a stroke and those with high-level paraplegia, and it has achieved good results in various medium to large hospitals as well as in home settings.

-

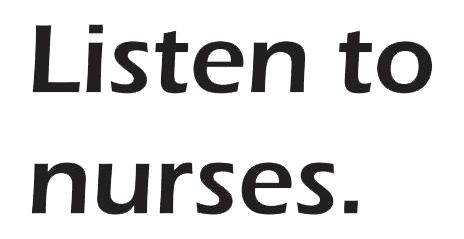

HF6008 Hospital Class III Tubular Medical Air M...Get A Quote

-

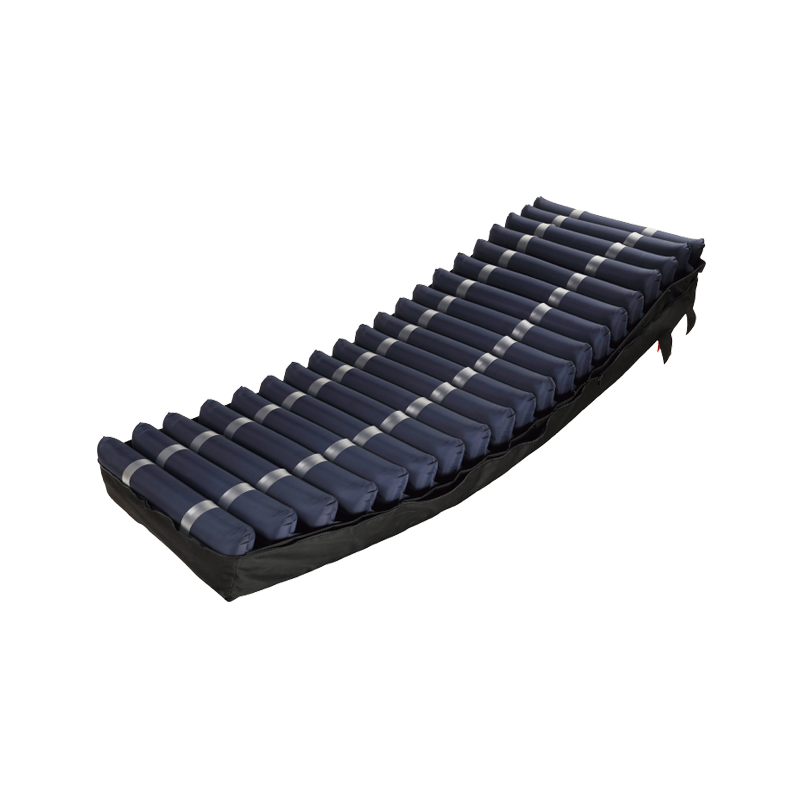

HF6002 Medical Alternating Pressure System tubu...Get A Quote

-

HF6002-17P+HF605 Wholesale Antibedsore Inflatab...Get A Quote

-

HF6001 New Style Yellow Blue Cheap Medical Bubb...Get A Quote

-

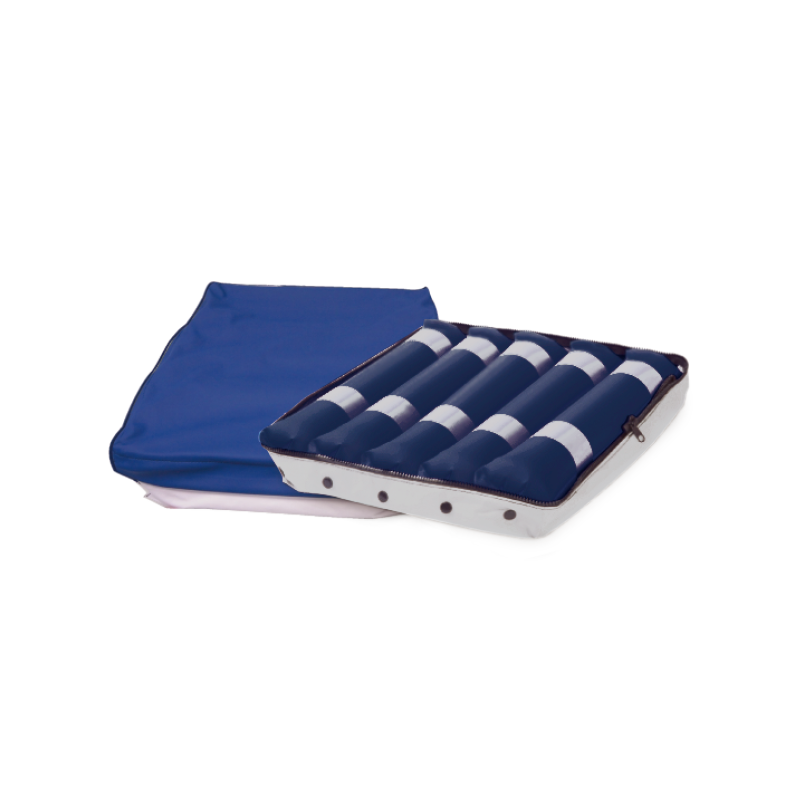

HF2002 Home Care Medical Seat Cushion With Digi...Get A Quote

-

HF6100 PVC Medical Water MattressGet A Quote

-

High-Quality Material and Advanced Technology

FOFO’s medical anti-decubitus mattresses are crafted using premium materials from Taiwan, ensuring exceptional durability and performance. Our mattresses are produced using a patented 225KW high-frequency machine, developed independently by FOFO. This cutting-edge technology allows for the creation of bubble mattresses through one-time moulding, ensuring uniformity and high-quality production. With the capacity to export 1.5 million mattresses annually, FOFO has established itself as a leader in the wound care industry, offering a range of solutions for the effective treatment and healing of pressure ulcers.

-

Variety of Options for Pressure Ulcer Treatment

FOFO provides a wide range of anti-bedsore mattresses and air cushions, designed to meet various patient needs. Our product lineup includes Class II-III models like the HF6002 series, available in 3″, 3.5″, 4.5″, and 5″ options, with multiple cell configurations ranging from 16 to 24 cells. These models feature PVC material covers, CPR capabilities, and ventilation, ensuring comfort and effective pressure relief. For Class III products like the HF6005 series, we offer zippered stretch covers, TPU coating, and additional ventilation features to enhance patient comfort and safety.

-

Enhanced Durability and Performance

FOFO mattresses are designed for long-lasting durability and superior performance. Our Class IV/V models, such as the HF6008 and HF6006 series, are available in 8″ and 5+3″ cell-on-cell configurations. These mattresses feature TPU material, providing enhanced strength and resilience. The inclusion of a zipper PU strength cover and additional ventilation ensures superior airflow and comfort. With features like CPR capabilities and optional pillows, these mattresses offer a comprehensive solution for patients requiring advanced pressure ulcer care.

-

Commitment to Safety and Compliance

At FOFO, we prioritize safety and quality compliance in all our products. Our mattresses and air cushions are made in accordance with stringent medical standards, including compliance with FDA regulations, ensuring their safety for healthcare applications. Designed to meet Class II-III medical requirements, FOFO products undergo rigorous testing to guarantee their effectiveness in treating and preventing pressure ulcers. Our commitment to high-quality materials and advanced technology makes FOFO an industry leader in the development of medical support surfaces.

FOFO’s medical anti-bedsore mattresses and air cushions are made of high-quality Taiwanese materials, combined with the company’s independently developed patented 225KW high-frequency technology, and use a one-time molding air cushion mattress production process to ensure the high quality and durability of the products. FOFO can export 1.5 million mattresses each year, providing solutions for various pressure sore treatments. Our product series includes different models of Class II-III, Class III and Class IV/V, covering 3″, 3.5″, 4.5″, 5″ and other specifications, equipped with PVC or TPU coated cover cloth, with CPR function and ventilation design to meet the needs of different patients and provide a comfortable and safe nursing experience. FOFO is committed to providing innovative care products for patients with pressure sores to promote wound healing and rehabilitation.

FOFO medical anti-pressure sore mattresses are made of high-quality Taiwanese materials, combined with self-developed 225KW high-frequency equipment, and innovatively use one-time molding technology to produce air bubble mattresses. 1.5 million mattresses can be exported annually. Our products provide a variety of trauma care solutions, effectively promoting the treatment and healing of pressure sores. We provide multiple series of anti-pressure sore mattresses and air cushions for customers with different needs, such as HF6002, HF6005, HF6008, etc., covering Class II-III, Class III, Class IV/V levels, suitable for care of different levels of pressure sores. FOFO is committed to providing customers with high-quality and innovative medical products to ensure the comfort and safety of patients.

-

Customer Needs ConsultationAt FOFO, we always put the care needs of patients first. We have a deep understanding of the specific needs of each patient and the use environment of the mattress through detailed communication with medical professionals. This stage provides detailed data support for subsequent design and customization.

-

Material Selection and Process DesignOur anti-bedsore mattresses use high-quality materials from Taiwan to ensure comfort and durability. Combining high-frequency welding technology and one-time molding bubble mattress production process, FOFO is able to provide mattresses of various sizes and configurations to meet the needs of different patients.

-

Technological Innovation and Patent SupportFOFO has a self-developed 225KW high-frequency machine. This patented technology provides higher precision and stability for the production of mattresses. Our original one-time molding process for bubble mattresses makes the performance of the mattress more reliable and can effectively prevent the occurrence of bedsores.

-

Customization and Personalized DesignDepending on the different conditions of the patients, we provide a variety of models and configurations of mattresses to choose from, including different bubble counts and layer heights. Whether it is 3", 3.5", 4.5" or higher design, FOFO can customize according to actual needs to ensure that every patient can get the most suitable care product.

-

Production drawings and quality standardsAfter the design phase is completed, FOFO's production team enters the production stage according to the confirmed CAD drawings. Each drawing will be strictly reviewed and modified to ensure that the final product meets the high standards of the medical industry.

-

Precision production and process guaranteeDuring the production process, we use high-end equipment and technology, including PVC and TPU coating materials, to provide solid protection and good breathability for the mattress. The bubble and layer height design of each mattress is carefully adjusted to ensure that the risk of bedsores is minimized.

-

Strict quality inspection and controlIn order to ensure the quality of the products, FOFO has established a strict quality control process. Each mattress will undergo multiple tests to ensure that its bubble structure, surface coating, CPR valve and other functions meet the requirements and can achieve the best results in actual use.

-

Massive production and global exportFOFO produces more than 1.5 million anti-bedsore mattresses every year to meet the needs of the global market. Our production line can efficiently handle large-volume orders, and each product undergoes strict quality inspection to ensure that it can meet international medical standards and is widely used in major medical institutions.

-

What is the primary function of anti-decubitus mattresses and air cushions?

The primary function of anti-decubitus mattresses and air cushions is to prevent and alleviate pressure ulcers (bedsores). They distribute body pressure evenly, reducing the risk of prolonged pressure on specific tissues. For patients who already have pressure ulcers, these products can help alleviate symptoms and promote wound healing. Additionally, they enhance comfort and improve sleep quality.

-

What types of anti-decubitus mattresses and air cushions are available?

There are several types of anti-decubitus mattresses and air cushions: Static foam mattresses: Made from foam materials of varying densities and thicknesses, they provide good support and cushioning. Alternating pressure mattresses: Comprised of multiple air cells that inflate and deflate alternately, shifting the pressure points on the body to promote blood circulation. Water mattresses: Use the flow of water to distribute pressure and provide a soft support. Gel mattresses: Gel materials offer excellent pressure distribution and cushioning, suitable for patients who are bedridden for long periods. Air cushions: Typically used on chairs or wheelchairs, they provide support and pressure distribution through inflation, ideal for patients who sit for extended periods.

-

Are air mattresses good for bedsores?

Compared with foam mattresses, alternating pressure air mattresses or overlays probably result in health benefits that outweigh their costs in preventing pressure ulcers. Static air mattresses or overlays may be better than foam mattresses for ulcer healing, but may cost more.

-

What type of mattress is best for bedridden patients?

Innerspring or hybrid mattresses and gel foam mattresses are useful in this scenario as they retain less heat. A memory foam mattress with an open cell structure is the best as it circulates the heat instead of trapping it, thus allowing you to get a good night's sleep.

-

What are the cleaning and maintenance tips for anti-decubitus mattresses and air cushions?

When cleaning and maintaining anti-decubitus mattresses and air cushions, keep the following in mind: Regular cleaning: Use mild cleaning agents and a soft cloth to wipe the surface. Avoid harsh chemicals that can damage the material. For removable covers or sleeves, follow the product instructions for washing and drying. Proper inflation: Ensure that air cushions are inflated to the recommended pressure to maintain their effectiveness. Inspect for damage: Regularly check for any signs of wear or damage, such as leaks or tears, and replace or repair as necessary. Store correctly: When not in use, store the products in a cool, dry place away from direct sunlight and extreme temperatures to prevent damage.